Introduction

This chapter includes the following topics:

INCONTROL Products and IOA

The Control-M/Tape tape management system is a component member of the INCONTROL by BMC family of products, a fully integrated suite designed to automate, manage and streamline operations on the z/OS mainframe. The INCONTROL family also includes client and server products that facilitate the automation of other platforms.

IOA

The Integrated Operations Architecture (IOA) is at the heart of the INCONTROL family of products. IOA has a common core of shared code as the foundation of its architecture design. INCONTROL's IOA environment has several inherent design advantages, including a common user interface and a shared data repository. A key feature of the IOA environment is its integrated application design, which includes:

-

Integrated User Notification

-

Management by Exception

-

Integrated Scheduling

-

Interdependency and Interrelationship Handling

-

Common Help Facility

-

Integrated Management Reporting

-

Common Method for Sharing Information

-

Unified Installation and Maintenance

-

Unified Security Implementation

-

Open Interface Design

INCONTROL

The INCONTROL family of products includes:

Table 1 List of INCONTROL Products

|

Product |

Description |

|---|---|

|

Control-M |

Automated Production Control and Scheduling System |

|

Control-M/Restart |

Restart Management System |

|

Control-M/Tape |

Removable Media Management System |

|

Control-M/Analyzer |

Automated Information Integrity System |

|

Control-D |

Output Management System Automatically schedules and controls every aspect of report processing and distribution, including report decollating, bundling, printing, online viewing, and archiving. |

|

Control-V |

Quick Access Archive Viewing System |

|

Control-D/

|

Report Retrieval and Display System |

|

Control-D/ Image |

Image Output Management System |

|

Control-O |

Console Automation System and Desired State Monitoring System The Control-O/COSMOS feature allows for status monitoring while maintaining all critical system objects in a desired and ideal status. |

Control-M/Tape: A Functional Approach

Control-M/Tape is designed to efficiently track and control all types of removable media.

Control-M/Tape

-

verifies that appropriate volumes are mounted and used

-

prevents the accidental erasure (scratch) of data stored on removable media

-

tracks, controls, and manages the movement of removable media throughout its life cycle

-

dynamically stacks files on removable media to increase media utilization

-

stacks removable media files in batch mode to increase the use of the media with minimal interference in production

-

provides immediate answers to online inquiries

-

simulates and forecasts future media management processing, enabling you to increase efficiency

-

interfaces with a variety of different robotic tape libraries, Virtual Tape Services (VTS), and on-site software products to fully automate tape management at your site

-

interfaces with a variety of different External Data Manager (EDM) applications, such as DFHSM and DMS/OS

Working together, the Control-M/Tape facilities and components automate tape management at your site and increase efficiency in tape usage. This chapter introduces these facilities and components from a functional perspective, beginning with the major components that comprise the heart of Control-M/Tape, and concluding with the minor components that enhance the functionality of Control-M/Tape.

Major Components

-

This section describes the major components essential to Control-M/Tape.

Control-M/Tape Rule Definitions

A Control-M/Tape rule is a set of parameters that define actions to be performed when a data set that satisfies specified selection criteria is created in the Control-M/Tape database. When such a data set is created, the rule is activated (that is, the actions specified in the rule are performed).

Each rule definition contains the following sections:

Table 2 Rule Definition Sections

|

Section |

Description |

|---|---|

|

General Parameters |

General information about the rule (for example, rule name, and priority of the rule). |

|

Selection Parameters |

Criteria that describe the data sets whose access triggers the rule. |

|

Action Parameters |

Actions to be performed when the rule is triggered. |

|

Basic Scheduling Parameters |

Days or dates on which a Control-M/Tape rule is eligible for triggering. |

Each rule only needs to be defined once. Once defined, a rule definition is saved. It can be modified later as required, and the changes saved. For more information on defining rules, see Rule Definition Facility.

Rule definitions are stored in members in partitioned data sets (libraries) as follows:

-

Related rule definitions are generally stored together in a single member called a rule table.

-

Multiple rule tables are stored together in partitioned data sets called rule libraries.

-

Multiple rule libraries can be defined.

Control-M/Tape Media Database

Control-M/Tape enables you to manage media on both a volume and a data set level. All volume and data set information is stored in the Media Database, which is an IOA Access Method database, thereby making the Media Database the main Control-M/Tape file. All media access is tracked in the Media Database.

As Control-M/Tape rules are implemented, changes to media management attributes (for example, vault patterns and retention periods) are updated in the Media Database. Because the Media Database always contains the most up-to-date information for each data set or volume, it forms the basis for Control-M/Tape operations.

-

Volumes are identified by a volume serial number (VOLSER). Volume information includes

-

All fields essential for effectively managing media utilization (for example, device type, and capacity used).

-

Fields describing media movement (for example, vault name, entry dates, and expiration date in each vault).

-

Statistical information (for example, last access dates, change dates, EXCP counts, and error counts).

-

Data sets are identified by the data set name, the volume that contains the data set, and the sequence number of that data set on the volume. Data set information includes:

-

All fields essential for protecting data integrity (for example, expiration date).

-

Security related fields (for example, the creating job name, user ID, and job account).

-

Media utilization fields (for example, capacity, and number of times used).

-

Statistical information fields (for example, last read and last write).

-

Basic data management fields (for example, block count, block size, and record format).

-

Minor Components

This section describes the minor components that enhance Control-M/Tape functionality.

New Day Processing: Automated Loading of Rules

Control-M/Tape rules are normally loaded when Control-M/Tape is brought up. A predefined list of rule tables is scanned for rules that should be activated for the current day or date. Rules whose day or date specifications (meaning, basic scheduling criteria) are satisfied are loaded into memory. To ensure that rules to be activated on a specific day are loaded for that day, it is highly recommended that you reload rules each day. Reloading of rules is performed automatically through the Control-M/Tape New Day procedure.

The New Day procedure also performs other tasks that need to be performed each day. This series of maintenance and housekeeping tasks is performed once a day at a specific time (usually the start of the working day). Control-M/Tape does the following through the New Day procedure:

Reloads Control-M/Tape rules

-

Expires unneeded data sets and volumes

-

Reassigns volumes to different vaults

-

Backs up the Media Database

-

Checks the integrity of the Media Database

-

Accumulates statistical information on the data sets created yesterday

Other tasks can optionally be added to the New Day procedure. Implementation and modification of the New Day procedure are described in detail in the Control-M/Tape chapter of the INCONTROL for z/OS Administrator Guide.

Pool Allocation

Pools are logical groupings of media (volumes) at your site (for example, a pool can be defined for each department in your organization). Organization of media information by pool can be particularly useful for allocating and budgeting removable media by department.

When a department’s job requests a scratch volume, Control-M/Tape determines the appropriate pool for that job according to user specified criteria (in a rule definition). Control-M/Tape then verifies that the mounted volume is from the correct pool.

For more information, see Pool Definition Screen.

Vault Management

Vaults are locations where removable media volumes can be stored as an alternative to the Active library. The movement of media to and from vaults or Active library (MAINLIB) is managed by the Vault Management facility. Vaulting requirements are established when data sets are created based on user-specified instructions defined in rules. These vaulting instructions are called the vault pattern.

For example, a volume may move to Vault A, then to Vault B, and then return to the Active library. Different retention periods can be specified at each location. A volume is scratched only when it has finished its vault pattern (meaning, is returned to the Active library (MAINLIB).

Vault management is performed by a utility. This utility, that runs on a daily basis, performs the following functions:

Table 3 Vault Management Utility Functions

|

Function |

Description |

|---|---|

|

Movement Between Locations |

Checks all retention periods at all vault locations to determine that volumes need to be transferred to different locations. |

|

Report Production |

Produces a distribution report that lists all volumes that should be moved to a new location or assigned a new slot number. |

|

Vault Pattern Recalculation |

If requested, recalculate vault patterns, according to updated rules. |

Retention Management

Control-M/Tape Retention Management determines how long the information contained in a data set or on a volume should be retained, and when that information can be overwritten.

The retention period of a data set is determined when the data set is created, according to the information specified through rules. The retention period of a volume is determined by the latest retention period of its data sets. Therefore, a volume becomes scratch only when all its data sets have been scratched.

A data set can only become scratch according to its retention parameters. It can only be overwritten (recreated or modified) if it is physically the last active data set on the volume.

There are two types of retention:

Table 4 Data Set Retention Types

|

Retention |

Description |

|---|---|

|

Normal Retention |

Established when the data set is closed properly. |

|

Abend Retention |

Applied if the data set is closed under abend, or not closed at all (for example, due to a system crash). |

The actual expiration of data sets and volumes is performed by a utility. This utility, that runs on a daily basis, performs the following functions:

Table 5 Functions Performed by Retention Utility

|

Function |

Description |

|---|---|

|

Retention Processing |

The retention specifications of all selected data sets are checked. Expired data sets are marked scratch in the Media Database. When all data sets on a volume are marked scratch, the volume becomes scratch. |

|

Report Production |

A report is produced that shows scratch volumes for a specific date. This report is an important tool for forecasting the availability of scratch volumes in each pool. |

|

Retention Period Recalculation |

If requested, the retention period of all or selected data sets and volumes is recalculated according to updated rules. |

Dynamic Data Set Stacking

The Dynamic Data Set Stacking facility automates and manages the creation of multiple files on a physical volume, while remaining totally transparent to the user. Control-M/Tape coordinates the entire administrative effort.

Control-M/Tape implements dynamic stacking during real-time processing. Instead of creating a data set on a scratch volume, Control-M/Tape can create the data set on a volume that already contains files but has enough free space. Control-M/Tape uses volume information to calculate the free space remaining on the volume. The amount of space required to hold the data set is calculated based on how much space previous versions of the data set required. Job parameters are changed automatically to direct the data set to the appropriate volume.

Stacking is enabled or disabled depending on user specified rules. In addition, the desired percentage utilization of all media is specified.

Control-M/Tape performs intelligent stacking by grouping data sets that have common characteristics (for example, similar expiration dates, same pool) on a single volume.

Report Generation

The following types of reports can be generated by Control-M/Tape:

-

Reports generated through the CTTRPT batch reporting facility with information produced from the Media Database.

-

Reports generated through the CTTSTKR batch reporting facility with information from the Stacking database.

-

Control-M/Tape special purpose reports, that are generated automatically as a result of various maintenance operations (for example, retention management).

-

Reports generated through the IOA KeyStroke Language.

Most Control-M/Tape reports are produced from information in the Media Database and the Trace file. The reporting facility can be activated at any time, even if Control-M/Tape is not active. For more information on reports generated by Control-M/Tape, see utility CTTRPT in the INCONTROL for z/OS Utilities Guide.

Robotic Tape Library Interfaces

Control-M/Tape can interact with the most popular robotic tape libraries (for example, StorageTek and IBM 3494/3495) to manage many tape management tasks at your site. The interface with the robots at your site allows Control-M/Tape to ensure that the information in the robotic tape library’s database is consistent with the Control-M/Tape Media Database.

For more information, see the robotic tape library interface and virtual tape server discussion in the Control-M/Tape Implementation Guide.

Write Once Read Many (WORM) Volumes

Control-M/Tape supports the use of Write Once Read Many (WORM) volumes and recognizes WORM volumes as special volumes.

WORM support in Control-M/Tape includes the following:

-

A WORM indication is assigned to WORM volumes.

-

The WORM Worldwide Unique Identifier (WWID) and the WORM Write Mount Count (WMC) are displayed and recorded in the MDB.

-

WORM volumes can be filtered at the volume level in the Inquire/Update (TI) screen.

In addition, the following utilities provide corresponding fields for filtering, updating, and tracking:

-

CTTSYNC - Update the Control-M/Tape Media database with WORM volumes according to OAM libraries.

-

CTTRPT - Generate reports based on WWID, WMC, and WORM indication.

-

CTTACP - Display WORM fields in the Trace file.

-

CTTMUP - Manually update WORM fields in the MDB.

Upgrading to version 9.0.21.100 requires the use of the ICE Automatic Exit Installation Tool (described in Exits, in the INCONTROL for z/OS Administrator Guide) to compile the CTTOAM member, which contains the necessary code for interfacing with the IBM OAM-managed automated tape libraries software.

IOA Log Facility

Important messages issued by Control-M/Tape are also written in the IOA Log file. The IOA Log file is a repository of messages issued by all INCONTROL products for z/OS. Through the IOA Log facility, the user can examine messages issued by Control-M/Tape.

AutoEdit Facility

The AutoEdit facility enables inclusion of special user-defined variables and system variables in rule definitions. AutoEdit variables are generally specified in place of hard coded values that change frequently (for example, current date). The variables are resolved (meaning, replaced with the appropriate values) during rule processing. Use of AutoEdit variables can eliminate the need to edit and update rules once they have been defined.

The values of user-defined variables are stored in memory and can be used for triggering of rules, jobs, and missions in other INCONTROL products.

For added flexibility, various AutoEdit functions and control statements can be used to manipulate variables and constants in a rule definition.

For more information on the AutoEdit facility, refer to the KeyStroke Language (KSL) User Guide.

KeyStroke Language

The KeyStroke Language (KSL) is a general purpose language that simulates, in batch, keystrokes entered in the IOA Online facility. KSL language statements are specified in "programs" called scripts. KSL scripts can be used to automate routine tasks, and to generate reports based on IOA and product specific repository files. For more information on KeyStroke Language, refer to the KeyStroke Language (KSL) User Guide.

Interaction With Other INCONTROL Products

Since Control-M/Tape is part of the INCONTROL family of products, Control-M/Tape capabilities influence, and are influenced by, other INCONTROL products.

Prerequisite conditions automate the scheduling of events between INCONTROL products. The user can establish dependencies between media access and other events.

Control-M/Tape can assign values to AutoEdit variables. AutoEdit variables can be saved in a member that can also be referenced by other INCONTROL products.

Control-M/Tape media analysis can automatically trigger Control-O rules, that can then perform Control-O automation tasks. Media analysis can also affect the processes of other INCONTROL products.

Control-M/Restart can automatically trigger the scratching of data sets in Control-M/Tape as part of the restart process.

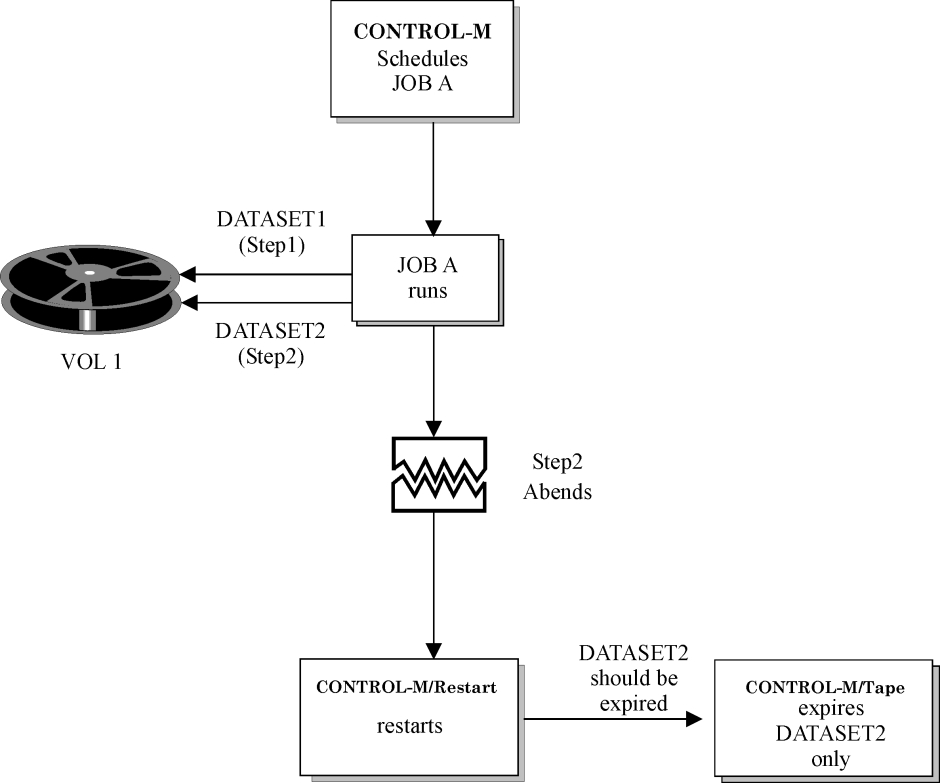

Figure 1 Interaction With Other INCONTROL Products

For example, the diagram above illustrates the following:

-

A job, JOB A, creates two data sets on volume VOL 1. The first data set (DATASET1) is created in Step 1. The second data set (DATASET2) is created in Step 2.

-

Step 2 of JOB A abends or ends NOT OK.

-

Control-M/Restart automatically restarts JOB A and notifies Control-M/Tape that DATASET2 should be expired.

-

Control-M/Tape immediately expires DATASET2.

The integrated INCONTROL environment, and resultant synchronization between the products, provides extensive automated operations capabilities.

Operation Modes

Control-M/Tape can be run in the following modes:

Table 6 Operation Modes

|

Mode |

Description |

|---|---|

|

Test mode |

Control-M/Tape works in parallel to other tape management systems at the site. Information is recorded in the Media Database, but Control-M/Tape does not intervene in any way (for example, prompts are not issued, unexpired data sets are not protected, and mount messages are not modified). Default. |

|

Phased mode |

Control-M/Tape works in parallel with other tape management systems at the site. Both products control and protect media at the site. |

|

Production mode |

Control-M/Tape exclusively controls all tape management processing at the site (for example, unexpired data sets are protected, and mount messages are modified). |

Mode can be specified globally for all Control-M/Tape operations, or for specific rules. For more information, see MODE: General Parameter.

Utilities

Utilities provided with Control-M/Tape are used to perform a variety of management functions and generate reports that assist in the efficient use of Control-M/Tape. These utilities (and relevant IOA utilities) are described in the INCONTROL for z/OS Utilities Guide. INCONTROL for z/OS Online facilities are described in Online Facilities.

Table 7 Trace Utilities

|

Utility |

Description |

|---|---|

|

CTTACP |

Retrieves database tracking information. |

|

CTTAFR |

Formats and initializes the Trace file. |

|

CTTCTRC |

Allocates and formats the Trace file. |

|

CTTRSM |

Recovers tape activity from SMF records. |

|

CTTTRB |

Synchronizes the Trace file and the Media Database backup process. |

Table 8 Stacking Utilities

|

Utility |

Description |

|---|---|

|

CTTGVL |

Provides a user interface to the Stacking facility. |

|

CTTSBD |

Performs data set stacking in batch mode. |

|

CTTSCA |

Detects data set contentions. |

|

CTTSTK |

Builds and updates the Stacking Database. |

|

CTTSTKR |

Generates stacking statistics reports. |

Table 9 Media Database Utilities

|

Utility |

Description |

|---|---|

|

CTTDLD |

Adds non-scratch volumes, adds and deletes scratch volumes, and converts from other tape management systems. |

|

CTTIDB |

Checks the integrity of the Media Database. |

|

CTTMER |

Merges records from an extract file (created by utility CTTSPL) into the Media Database. |

|

CTTMUP |

Performs manual update of the Control-M/Tape repository. |

|

CTTRCV |

Recovers Media Database contents using the Trace file. |

|

CTTRSM |

Recovers Media Database contents using SMF records. |

|

CTTSPL |

Copies or moves (Splits) specified records from the Media Database. |

|

CTTSYNC |

Synchronize the Media Database with other software databases. |

Table 10 Daily Management Utilities

|

Utility |

Description |

|---|---|

|

CTTRTM |

Performs retention management. |

|

CTTVTM |

Performs vault management. |

As of version 6.1.00, all Control-M/Tape databases use the IOA Access Method format. Certain utilities that handled the database files in previous versions were replaced by IOA utilities, as noted in Table 11.

Table 11 Database Handling Utilities for IOA Access Method Databases

|

Utility |

Description |

|---|---|

|

CTTBIX |

Builds the index of the Media Database. |

|

CTTDBIB |

Builds the indexes of the Stacking Database. |

|

IOADBF |

Allocates and formats an IOA Access Method file. This utility replaces both the CTTDBF and CTTCRDF utilities as of version 6.1.00. |

|

IOADIG |

Verifies the integrity of an IOA Access Method file data component. This utility replaces the CTTDBID utility as of version 6.1.00. |

|

IOADII |

Verifies the integrity of an IOA Access Method file index component. This utility replaces the CTTDBII utility as of version 6.1.00. |

|

IOADLD |

Loads IOA Access Data components from a sequential data set. This utility replaces the CTTDBDLD utility as of version 6.1.00. |

|

IOADPT |

Prints records, in dump format, from an IOA Access Method database to a SYSOUT. This utility replaces the CTTDBPRT utility as of version 6.1.00. |

|

IOADUL |

Unloads IOA Access Data components to a sequential data set. This utility replaces the CTTDBDUL utility as of version 6.1.00. |

Table 12 Miscellaneous Control-M/Tape Utilities

|

Utility |

Description |

|---|---|

|

CTTRPT |

Generates reports and from extracted Media Database information. |

|

CTTTPI |

Initializes tapes, erases tapes, and produces a detailed report of the logical and physical contents of a volume. |

Operator Notification (the Shout Facility)

Control-M/Tape can send messages to specified locations in response to detected access of specified data sets. For each Shout message to be sent, the user defines the message, the degree of urgency, and the location to which the message should be sent.

For more information about the Shout facility, see DO SHOUT: Action Parameter.

Rule Scheduling using the Calendars: IOA Calendar Facility

Specification of scheduling criteria for rules can be simplified by calendar definitions. A calendar definition consists of a defined schedule (for example, Mondays through Fridays in each week in each month) that can be applied to rules.

Calendars are defined in the IOA Calendar facility. Each calendar is assigned a unique name, that can be specified in rule definitions. A particular calendar (meaning, schedule) only needs to be defined once.

Specification of the name of a calendar in rule definitions causes that calendar schedule to be used to schedule those rules.

Two types of calendars can be defined: Regular and Periodic.

Regular calendars contain schedules that can be easily defined using Basic Scheduling parameters, These calendars consist of scheduling date or days (of the week) that can be fixed according to monthly patterns.

|

WEEKDAYS |

Calendar schedules rules each Monday through Friday in each month. |

|

WEEKENDS |

Calendar schedules rules each Saturday and Sunday in each month. |

|

QUARTERLY |

Calendar schedules rules on the last day of each quarter: March 31, June 30, Sept. 30, Dec. 31. |

Regular calendars are useful when many rules have the same schedule. The schedule can be defined once in a calendar and the calendar can be specified in relevant rules to individually define that schedule in each rule definition

Periodic calendars are useful in situations where basic scheduling criteria would be difficult to define because they do not easily conform to fixed day or date of the week or month formatting.

|

PAYCAL |

Schedules missions (for example, payroll) every other Wednesday. Scheduling occurs on the first, third, and (if there is one) fifth Wednesday of some months. Scheduling occurs on the second and fourth Wednesday of other months. |

The IOA Calendar facility is accessed by option 8 of the IOA Primary menu. It is described in Online Facilities.

Interface to IBM Health Checker

When the Control-M/Tape interface to the IBM Health Checker facility is enabled, IBM Health Checker runs appropriate checks to ascertain the status of vital Control-M/Tape components. If potential problems are detected, you receive alerts through the Health Checker reporting facilities. For more information about the IBM Health Checker, see the IBM Health Checker for z/OS User's Guide.

IBM Health Checker performs checks for the following healthy states of Control-M/Tape components:

-

Major Control-M/Tape control blocks are accessible.

-

All Tape Label Processing (TLP) Exit routines of Control-M/Tape are installed and active.

-

Control-M/Tape Dynamic Write to Operator (WTO) interface is active.

-

The SVC routine installed by Control-M/Tape is active.

The Control-M/Tape interface to IBM Health Checker is controlled by parameters HCHECKT and HCINTRVT in the CTTPARM member of the IOA PARM library. These parameters specify whether to enable the Health Checker interface and the time interval for health checks.

The Control-M/Tape interface to the IBM Health Checker facility is supported on z/OS versions 2.2 and later.

Online User Interface

Control-M/Tape provides an online user interface that enables the user to:

-

Interface with most of the previously described facilities.

-

Immediately access up-to-date information on media management.

-

Intervene in the processes of media management.

The Online user interface is provided through online facilities that are accessed by the IOA Primary Option menu.

Certain online facilities are unique to Control-M/Tape, and other facilities are shared by many or all INCONTROL for z/OS products.

All INCONTROL and Control-M/Tape online facilities are described in detail in Online Facilities. They are all outlined briefly in the following topics.

Your INCONTROL administrator can limit the options displayed on a user-by-user basis and can alter option numbers and customize option descriptions. Product supplied default options are discussed in this overview.

Rule Definition Facility

The Control-M/Tape Rule Definition facility is accessed through option TR of the IOA Primary Option menu. It is the main online facility for creating, defining, modifying, and deleting:

-

Rule libraries

-

Rule tables

-

Rule definitions

This facility can also be used to edit an existing rule definition.

Pool Definition Screen

The Pool Definition screen is accessed through option TP of the Primary Option menu. This screen is used to view create and modify pool definitions.

Pools are defined according to logical categories that exist at your location (for example, a pool can be defined for each department in your organization). This method is particularly useful for allocating and budgeting removable media by department.

A certain number of scratch volumes should be allocated for each pool. Pools are defined to Control-M/Tape through the Pool Definition screen. Pool definitions are stored in tables (members) that are stored in definition libraries.

When a department’s job requests a scratch volume, Control-M/Tape determines the appropriate pool for that job according to rule specifications. Control-M/Tape then ensures that the mounted volume is from the correct pool.

Once a pool is defined, only data sets associated with that pool can use volumes from that pool.

Vault Definition Screen

The Vault Definition screen is accessed by option TV of the IOA Primary Option menu. This screen can be used to view, modify and create vault definitions.

A vault is a media storage location (usually, but not necessarily, off-site) for inactive volumes (for example, backup volumes). A vault definition defines the vault name, location, and optionally, the capacity of the vault.

Off-site vaults are called Remote vaults. Vaults at the same location as the active library are called Local vaults.

The smallest unit that can be transferred to a vault is a volume. Volumes can be transferred from vault to vault, or back to the active library, based on vault patterns.

Vault patterns dictate the movement of volumes between storage locations, based on retention periods specified (in rule definitions) for each location. A vault pattern that is defined in a rule can specify an unlimited number of vaults.

Distribution reports, pick lists, and inventory reports can be printed for each vault.

Vaults are defined to Control-M/Tape using the Vault Definition screen. Vault definitions are stored in tables (members) that are stored in definition libraries.

Inquire and Update of the Media Database

The Media Database list is accessed using option TI of the IOA Primary Option menu. This screen displays a list of selected data sets and volumes in the Media Database. The data sets and volumes to be displayed are selected using the Inquiry Update entry panel.

In this screen you can:

-

Request additional information for any volume or data set.

-

List all data sets on a given volume, or all volumes where a specific data set resides.

-

List all volumes of a multi-volume chain to which a specific volume belongs.

-

Update displayed information.

-

Expire a volume or data set.

-

Extend the expiration date of a volume or data set.

-

Check out a volume.

-

Reenter a volume that was checked out.

-

Recall a volume from a vault.

-

Send a volume to a vault.

-

Indicate that a volume was cleaned.

-

Print labels.

-

Delete or undelete a volume.

External Volume Check-In Screen

The External Volume Check-In screen is accessed through option TC of the IOA Primary Option menu. This screen in used for the definition and addition of external volumes (for example, volumes sent from other sites) to Control-M/Tape.

When this screen is entered, previously saved data on external volumes is displayed on the screen (by default).

For more information, see the section External Volume Check-In Facility.

IOA Conditions/Resources Screen

The IOA Conditions/Resources screen is accessed through option 4 of the IOA Primary Option menu. It displays information from the IOA Conditions file, that contains the list of all existing prerequisite conditions, and the Control-M/Tape Resources file, that contains the list of Quantitative resources and Control resources. The IOA Conditions/Resources screen enables the user to:

-

View IOA prerequisite conditions.

-

View Control-M/Tape Quantitative resources.

-

Add or delete prerequisite conditions and/or resources.

-

Change the available quantity of Quantitative resources.

IOA Log Screen

IOA messages are written to the IOA Log file. Messages can be viewed through option 5 in the IOA Primary Option menu. These messages record every significant event in the life of a job, started task, mission, rule, and so on under the control of INCONTROL products. This includes messages generated for normal processing occurrences and error conditions (if any) encountered during processing. The IOA Log also contains messages directed to the IOA log from the Shout facility.

The IOA Log file stores a limited number of messages (specified by an installation parameter). Each new entry in the IOA Log file overwrites the oldest existing entry.

The user can filter IOA Log file contents displayed in the IOA Log screen by a filter window that allows specification of viewing criteria for each field in the IOA Log screen.

Control-M/Tape Concepts

The following Control-M/Tape concepts are discussed below:

-

Control-M/Tape Repository and the IOA Core

-

SL-NAME Concept

-

Active Library

Control-M/Tape Repository and the IOA Core

A differentiation is made between files belonging to a particular product such as Control-M/Tape, and files that are shared among INCONTROL products.

Files belonging to a particular product are located in the repository for that product. The Control-M/Tape repository consists of the following files:

Table 13 Control-M/Tape Repository Files

|

File |

Description |

|---|---|

|

Rule Tables |

Files containing Control-M/Tape rule definitions |

|

Media Database |

All information about volumes and data sets managed by Control-M/Tape. As of version 6.1.00, this database is in IOA Access Method format. For more information, see Control-M/Tape Media Database. |

|

Trace File |

A record of all important activities in the Control-M/Tape environment. The Trace file is the key vehicle for recovery, and for production of reports on Control-M/Tape activity. Types of records found in the Trace file include:

IOA Functional monitor requests. |

|

Stacking Database |

Statistical information on each data set, which enables Control-M/Tape to estimate the amount of space required for the data set. Information about each previous generation of a data set is used to calculate the space required to store each data set. As of version 6.1.00, this database is in IOA Access Method format. Prior to version 5.1.4, this database was called the Stacking Statistics database. |

Shared INCONTROL files are collectively referred to as the IOA Core. The IOA Core consists of the following files:

Table 14 IOA Core Files

|

File |

Description |

|---|---|

|

IOA Log File |

File in which all messages issued by INCONTROL products are recorded. |

|

IOA Conditions File |

File that lists the available conditions identified and tracked by the IOA Functional monitor (described below). |

|

IOA Manual Conditions File |

File listing prerequisite conditions that must be added manually (meaning, prerequisite conditions required by Control-M jobs or Control-D missions and that are not automatically added by other jobs or missions in the Active Jobs and Missions files). |

|

IOA Calendar Tables |

Files containing IOA calendar definitions. |

|

Dynamic Destination Table |

File containing a list of destinations for messages issued by the IOA Shout facility. |

SL-NAME Concept

When checking in external volumes, the volser of a volume being checked may be identical to the volser of a volume already in the Media Database. This creates a problem because the volser must be a unique identifier of a volume in the Media Database.

To solve this problem, Control-M/Tape stores volume identification information in the following way:

-

When a volume is checked in, the user assigns a new unique volser to the volume. The new unique volser is recorded in the VOLSER field of the volume record in the Media Database.

-

The original volser value (that matches the Standard Label of the volume) is recorded in the SL-NAME field in the volume record in the Media Database.

-

From this point on, whenever this checked-in volume is accessed, the new volser is used to identify the volume (including MVS Catalog if cataloged, JCL references to the volume, and so on).

For more information, see SL-NAME Concept.

Active Library

The Active library (called MAINLIB) is the on-site media storage location for volumes. The smallest unit in the Active library is the data set. Each data set has an expiration date associated with it.

Data sets are stored on removable media volumes in the Active library. If space exists, several data sets can be stored on one volume. When necessary, one data set can span several volumes.

Data set records are created and expired in the Active library. During the lifetime of a data set, the volumes on which it is stored may be transferred to various vaults.

Several methods exist for adding volumes to the Control-M/Tape Active library:

-

performing a conversion of existing data when first implementing Control-M/Tape at your site

-

For more information, see the INCONTROL for z/OS Installation Guide.

-

manually defining new volumes using the CTTDLD utility, described in the INCONTROL for z/OS Utilities Guide

-

setting Control-M/Tape to add volumes dynamically upon volume access (Automatic Check-In)

-

using the External Volume Check-In Facility

Date Definition Concepts

The following of date definitions concepts are discussed below:

-

System Date

-

Working Date

-

Date Standards and Date Field Formats

-

Prerequisite Conditions

-

Prerequisite Condition Dates

System Date

Date as supplied by the operating system. This date should reflect the actual calendar date starting and ending at midnight.

Working Date

Many sites do not use midnight as the formal time for changing to a new date. A site, for example, may determine that all processing performed between the hours of midnight and 6:00 a.m. belongs to the previous day’s processing. In this case, the installation working date at the site changes at 6:00 a.m., not at midnight.

The working date (meaning, the time at which the date changes at the site) is defined in the Control-M/Tape installation parameters. The New Day procedure is generally triggered at the beginning of the working day.

Date Standards and Date Field Formats

Date standards and date field formats use either Gregorian or Julian dates.

Gregorian Dates

Gregorian dates are indicated in the guide by the following symbols:

Table 15 Gregorian Date Symbols

|

Symbol |

Description |

|---|---|

|

dd |

Day of the month (01 – 31) |

|

mm |

Month (01 – 12) |

|

yy |

Last two digits of the year If the last two digits in the specified year are a number less than 56, IOA presumes that the year is in the 21st century (for example, if yy=15, the year 2015 would be presumed). Otherwise, IOA presumes that the year is in the 20th century (for example, if yy=80, the year 1980 would be presumed). |

|

yyyy |

Four digits of the year |

Whether a field holds a 4-character date (month and day), a 6-character date (month, day and 2-digit year) or an 8-character date (month, day and 4-digit year) depends on the field. However, the format of the 4-character, 6-character or 8-character date depends on the installation defined date standard.

INCONTROL products support three date standards for Gregorian dates. Each standard has an 8-character format, a 6-character format and a 4-character format. Only one Gregorian date standard is defined at any site.

These supported Gregorian date standards are described in the chart below.

Table 16 Standard Gregorian Dates

|

Standard |

4-Character Date |

6-Character Date |

8-Character Date |

|---|---|---|---|

|

MDY |

mmdd |

mmddyy |

mmddyyyy |

|

DMY |

ddmm |

ddmmyy |

ddmmyyyy |

|

YMD |

mmdd |

yymmdd |

yyyymmdd |

Julian Dates

Julian dates are indicated in the guide by the following symbols:

Table 17 Julian Date Symbols

|

Symbol |

Description |

|---|---|

|

jjj or ddd |

Day of the year (001 – 365 or 366, as appropriate for the year) |

|

yy |

Last two digits of the year |

|

yyyy |

Four digits of the year |

Julian date fields have either three, five, or seven characters. Whether a Julian date field holds a 3-character date (day of year only), 5-character date (day of year and 2-digit year) or a 7-character date (day of year and 4-digit year) depends on the field definition. However, the format of the date depends on the installation defined date standard.

For example, the Julian date for the calendar date of 28 February 2000 would be represented in jjj or ddd format as 059, in yyjjj or yyddd format as 00059, and in yyyyjjj or yyyyddd format as 2000059.

Prerequisite Conditions

A prerequisite condition is a user-defined descriptive name given to a certain situation or condition. Prerequisite conditions can be specified in a Control-M/Tape rule definition using a DO CONDITION statement.

Prerequisite conditions can serve as a method of communication between Control-M/Tape and the other INCONTROL products at your site.

Control-M/Tape uses prerequisite conditions to track the status of various aspects of the environment. When the status of a specific aspect of the environment changes, a Control-M/Tape rule can set or delete a condition to indicate this, and then subsequently trigger jobs, rules, or missions in other INCONTROL products whose execution is dependent on the status of this condition.

Prerequisite Condition Dates

DO CONDITION statements each provide a field used to specify a date for each prerequisite condition. A DO CONDITION prerequisite condition that is added with a particular date cannot satisfy a statement in a job, rule, or mission of another INCONTROL product in that this prerequisite condition is specified with a different date.

Communities

Communities Support Center

Support Center YouTube

YouTube Twitter

Twitter Facebook

Facebook LinkedIn

LinkedIn