Implementation Strategy

This chapter includes the following topics:

Overview

Control-M/Tape can have a major impact on the management and control of all your removable media. Control-M/Tape can apply automated media management to every component of your operations environment and drastically reduce the need for human intervention and consequent errors.

Control-M/Tape is gradually phased through operation in various modes, culminating in a fully operational Control-M/Tape and termination of your existing tape management system. Gradual transition from the existing tape management system to Control-M/Tape through the various Control-M/Tape operation modes is described in this guide.

Advanced features and customization should be added only when basic Control-M/Tape functioning has been tested and Control-M/Tape is already operating in production mode.

Control-M/Tape operation modes play a central role in conversion to Control-M/Tape. It is therefore important to understand the differences between the various modes and the role they play in Control-M/Tape implementation.

Control-M/Tape operation mode is specified using the MODET parameter in the CTTPARM member as shown in the following screen:

000001 **************************************************

000002 * CONTROL-M/TAPE SOURCE PARAMETERS MEMBER

000003 * ----------------------------------

000004 * CREATED BY ICE ON: 2001/10/14 17:08

000005 * USERID: K27

000006 **************************************************

000007 *------------------------------

000008 * INITIALIZATION SECTION

000009 *------------------------------

000010 INIT MODET=PROD, GLOBAL MODE (PROD,TEST,PHASED)

000011 DYNINTR=Y, CREATE DYNAMIC INTERFACES IN MVS (Y/N)

000012 DYNSVC=Y, DYNAMICALLY INSTALL THE SVC (Y/N)

000013 SVCNUM=243, CONTROL-M/TAPE SVC NUMBER

000014 TSSALLOC=Y, SUB-SYSTEM CAN BE DYNAMICALLY ADDED (Y/N)Each time Control-M/Tape mode is modified, tape processing must be halted and tape management data should be reconverted. This is because the processing of tapes during data conversion can result in discrepancies between the existing tape management system database and the Control-M/Tape Media Database.

Conversion of tape management data is described briefly in this chapter. For a more detailed explanation of this process, see the Control-M/Tape Conversion Guide.

Plan Implementation Strategy

Before implementing Control-M/Tape, it is important to review your current system. Information gathered at this stage will help determine procedures used later during Control-M/Tape implementation. Some of this information will also be used to determine appropriate values for certain Control-M/Tape installation parameters.

Answer the following questions about your current tape management configuration:

-

What is the existing tape management system?

-

What automated tape libraries are used?

-

What external data manager (EDM) is used?

-

What restart management software (if any) is used?

-

What reports are generated by your current tape management system?

-

How is tape movement and storage organized?

-

What security product is used and how is it implemented?

-

What additional tape management issues are relevant at your site?

-

How (meaning, with what configuration) was Control-M/Tape installed?

-

Who will be responsible for implementation tasks?

-

Where are Control-M/Tape repository files allocated?

Each of these questions is described in detail below.

What is the Existing Tape Management System?

Determine the name and release of the tape management software that is being replaced by Control-M/Tape.

Automatic conversion programs currently exist for sites with CA-1, CA-TLMS, CA-EPIC/MVS, DFSMSrmm, and the MVS Catalog (for sites with no tape management system). If you are using a different system (that is, one not listed here) to manage your tape library, it is recommended that you contact your INCONTROL representative before implementing Control-M/Tape.

A conversion program for sites with Zara is also available from BMC Customer Support.

Information Required

-

Name and release number of the existing tape management system.

-

Name and location of relevant files and libraries (for example, for CA-1, name and location of the TMC, RDS, and VPD files).

What Automated Tape Libraries Are Used?

Information Required

-

Name (vendor) and model of the automated tape libraries in use at your site.

-

Software configuration for the automated tape libraries.

If StorageTek automated tape libraries are in use at your site, it is important to note whether HSC, CSC, and Expert Library Manager (ExLM) software is used.

What External Data Manager (EDM) is Used?

Control-M/Tape can interface with a variety of different External Data Managers (EDMs). For more information about Control-M/Tape/EDM interfaces, see External Data Managers

Information Required:

-

the name of EDMs in use at your site (for example, DFSMShsm)

-

for each of the EDMs at your site, determine the following:

-

whether the existing tape management system has an interface to the EDM

-

the identifiers of EDM-controlled data sets (for example, program names, or data set name prefixes)

-

the name and location of the EDM JCL procedure

-

What Restart Management Software (if any) is Used?

Determine if a restart management package (for example, Control-M/Restart) exists at your site, and if the existing tape management system interfaces with it.

If such an interface exists, determine the library naming conventions for the restart management package, and where the interface exit routine resides (meaning, in what load library).

Information Required

-

Name of the restart management package in use at your site.

-

Library naming conventions for the restart management product.

-

Name of the load library containing the exit routine used by the restart management product.

What Reports are Generated by the Current Tape Management System?

Determine reports generated by the existing tape management system, and who receives those reports (meaning, which recipients should be notified of a change to the tape management system).

Control-M/Tape has a versatile reporting facility that enables you to produce reports compatible with those produced by the existing tape management system. Compatible reports are compared during implementation to evaluate Control-M/Tape performance in a format familiar to you and your tape management staff.

Information Required

-

Name and location of the reports generated by the existing tape management system.

-

Format of tape management reports currently in use at your site (for example, information included in the report).

How is Tape Movement and Storage Organized?

List all on-site and off-site tape storage facilities. For each of these facilities determine:

-

Location and size.

-

Types of media stored in the location.

-

Naming conventions.

-

Slot or Box configuration.

-

Amount of traffic to and from the storage facility.

-

Identify existing procedures for handling tapes received from external sources (for example, other data centers or vendors).

What Security Product is Used and How is it Implemented?

Determine which security product is in use at your site (for example, CA-TOP SECRET, CA-ACF2, or RACF).

Determine how the security package interacts with the existing tape management system.

Information Required

-

Name of the security product.

-

List of tape management entities protected by current security definitions.

What Additional Tape Management Issues are Relevant at Your Site?

Determine if DFSMS is used at your site to manage tape data sets (meaning, system managed tape data sets).

Determine if special EXPDT keywords are used in JCL at your site (for example, EXPDT=99000, and EXPDT=99365).

No JCL changes are needed to support information in EXPDT keywords under Control-M/Tape. However, certain Control-M/Tape installation parameters will need to be adjusted according to whether these keywords are in use, and for which product (CA-1 or CA-TLMS).

Determine if other software products at your site interact with the existing tape management system.

Information Required

-

Location of JCLs using EXPDT keywords.

-

Names and descriptions of other components of your computing environment that interface with your current tape management system.

How Was Control-M/Tape Installed?

If Control-M/Tape was initially installed using the default configuration (meaning, a small Media Database was created for testing purposes), review the following information to ensure that Control-M/Tape is set up properly for your production environment.

Information Required

-

Sizes allocated for Control-M/Tape libraries (Control-M/Tape installation steps 5.1, 5.2, and 5.3). The sizes used for Control-M/Tape implementation must reflect actual site usage.

-

Installation parameter settings (in CTTPARM). These parameters must be adjusted according to information gathered while reviewing the current system (described above).

-

Password assigned for Control-M/Tape.

Who Will be Responsible for Implementation Tasks?

Compile a list of the personnel who will be involved in Control-M/Tape implementation.

Information Required

-

The following is a sample list of human resources and their respective tasks during Control-M/Tape implementation. The actual list may vary according to site management requirements. Identify the relevant personnel for future reference.

Table 1 Human Resources for Control-M/Tape Implementation

Resource

Responsibility

Tape Library Administrator

Coordination of all aspects of Control-M/Tape implementation.

SMP/e Administrator

Control-M/Tape installation and application of periodic maintenance.

Security Administrator

Security setup and support.

Systems Programmer in Charge of EDMs and Backups

Application of interfaces to External Data Managers (EDMs) and other related software.

Production Administrator

Integration of Control-M/Tape procedures into the production schedule.

Interface with restart management software (for example, Control-M/Restart).

Operations Personnel

Use of Control-M/Tape features. These individuals typically undergo Control-M/Tape training before or during Control-M/Tape implementation. Contact your local INCONTROL representative for information about available training options.

Where are Control-M/Tape Repository Files Allocated?

Determine where each file in the Control-M/Tape repository is allocated. The Control-M/Tape repository consists primarily of the following files:

Table 2 Control-M/Tape Repository Files

|

File |

Description |

|---|---|

|

Media Database |

All information about data sets and volumes managed by Control-M/Tape. |

|

Stacking Database |

Statistical information on each data set. Used for calculating the amount of space needed for storage of each data set. |

|

Trace file |

A record of all important activities in the Control-M/Tape environment. Used for recovery of the Media Database and for tracking. |

The Media Database and the Stacking Database are each composed of two physical files:

Table 3 Media Database and the Stacking Database

|

File |

Description |

|---|---|

|

Data file |

Contains information stored in the file, as described in Table 2. |

|

Index file |

Provides keyed access to information in the Data file. |

Additional considerations for Control-M/Tape file allocation are described below.

Performance

For optimum performance, data and index files should reside on separate DASD volumes and the Trace file should reside on yet a different volume. This requires a minimum of three separate DASD volumes.

Figure 1 File Allocation

Allocating files differently than described above may result in poor performance.

You can choose to allocate files differently for operation during Global Test mode. However, it is recommended that you use file allocations during Global Test mode that match the allocations that you expect to use for operation of Control-M/Tape in Global Production mode. This will enable you to accurately evaluate Control-M/Tape performance (for example, processing time) while operating in Global Test mode.

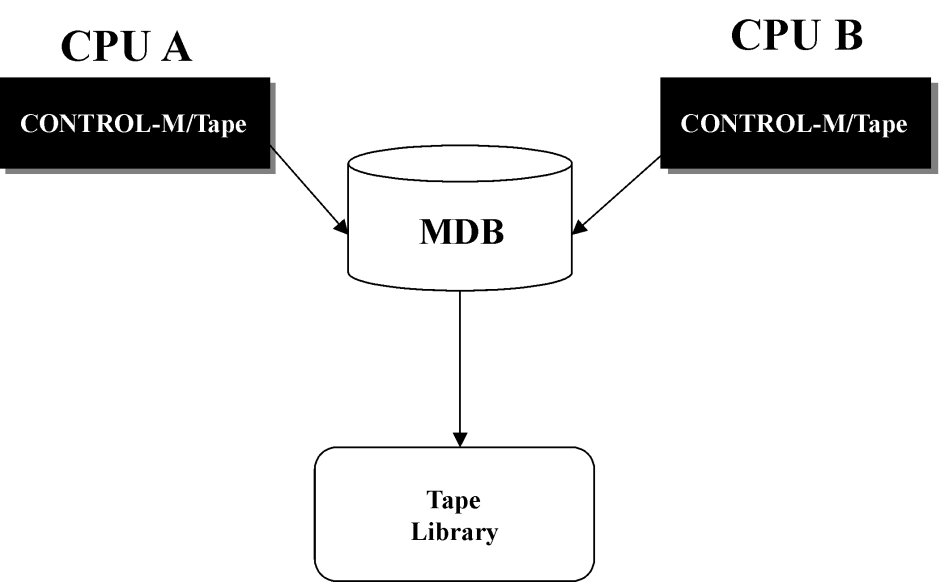

Multi-CPU Considerations

If two or more CPUs share one Control-M/Tape (installed on shared DASD) and one Media Database at your site, this Media Database must be stored on shared DASD.

Figure 2 Shared Media Database and Control-M/Tape Configuration

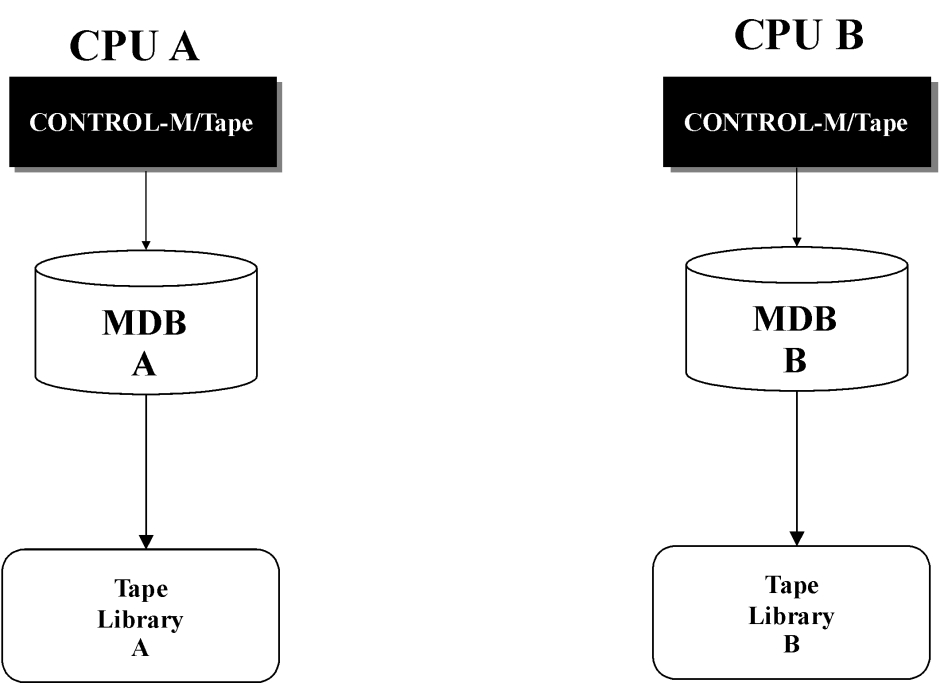

If different copies of Control-M/Tape at your site each use their own Media Database, it is highly recommended that you physically divide your tape library (meaning, tapes managed by each Control-M/Tape should be stored separately)

Figure 3 Separate Media Database and Control-M/Tape Configuration.

Convert Tape Management Data

Conversion is the process that extracts information stored in the existing tape management system and formats the data so that it can be used by Control-M/Tape. Programs supplied with Control-M/Tape enable you to automatically perform many of the steps necessary for conversion. The actual process of conversion differs, depending on the tape management system currently in use at your site.

Conversion is typically performed before switching Control-M/Tape modes (described below). Conversion may need to be performed multiple times (usually during operation in Global Test mode) while Control-M/Tape is synchronized with the existing tape management system.

Conversion to Control-M/Tape is described for the following products:

-

CA-1

-

CA-TLMS

-

CA-EPIC/MVS

-

DF/SMSrmm

-

MVS Catalog

For more information about the conversion process and conversion from specific products, see the Control-M/Tape Conversion Guide.

Global Test Mode

This mode allows you to test Control-M/Tape without affecting the production environment. Global Test mode is activated after the Media Database and Control-M/Tape rules have been created from information extracted from the tape management system being replaced.

In Global Test mode, the existing tape management system manages the production environment (for example, decides whether to accept a tape, protects data sets, issues prompts to the operator, uncatalogs expired data sets). Control-M/Tape updates the Media Database when its decisions match those of the existing tape management system. Control-M/Tape also sends warning messages to the Job log, System log, or Operator console if there is a contradiction between what the existing tape management system is doing and what Control-M/Tape would do if it were in Global Production mode.

In this mode, operators compare reports (for example, scratch reports, vault reports) generated by the existing tape management system to analogous reports produced by Control-M/Tape.

When the two systems’ reports match and Control-M/Tape operates according to your expectations, the next step is to enable Control-M/Tape and the other tape management system to operate simultaneously (in Global Phased mode).

Global Phased Mode

Global Phased mode is used when you are reasonably certain that Control-M/Tape will operate in the same way as the existing tape management system. This mode enables both Control-M/Tape and the existing tape management system to be fully operational simultaneously. The objective of Global Phased mode is to check the execution of Control-M/Tape in the production environment.

In this mode, Control-M/Tape and the existing tape management system each rely on their own media management decisions. These decisions must be the same. This is usually not a problem since Global Phased mode is used only after the Control-M/Tape Media Database and existing tape management system database have been synchronized (while Control-M/Tape was in Global Test mode).

During Global Phased mode, extended media management, such as automated tape library utilization, can be tested and "phased in" gradually. Procedures to be performed at the beginning of the working day and tape initialization requirements can also be implemented while in Global Phased mode.

Optionally, you can allow Control-M/Tape to operate in production mode for selected libraries while the other tape management system controls and manages media processing for all other libraries.

Global Production Mode

In Global Production mode, Control-M/Tape completely controls all tape processing at your site.

This mode is used when testing has been completed and you are certain that Control-M/Tape functions in the same manner as your existing tape management system. Before Global Production mode is specified, the existing tape management system must be removed from the system. Be sure to remove static system hooks in operating system routines that were used by the tape management system that is being replaced by Control-M/Tape.

Control-M/Tape Interfaces

Control-M/Tape can interface with a variety of different components of your computing environment. The interfaces for these components are implemented at various stages during Control-M/Tape implementation. Each type of interface is described in detail later in this guide.

Interfaces with the following software components are provided:

-

Automated Tape Library and Virtual Tape Server, described in Chapter8, "Automated Tape Library Interface and Virtual Tape Server".

-

External Data Managers, described in Chapter7, "External Data Managers".

-

Security Software, described in the Control-M/Tape chapter of the INCONTROL for z/OS Security Guide.

-

Restart Management software, described in the section on Control-M/Restart support in the Control-M/Tape chapter of the INCONTROL for z/OS Administrator Guide.

Implement Advanced Control-M/Tape Features

When Control-M/Tape is operating in Global Production mode, additional functionality can be added by customizing and tuning the existing tape management definitions, and by implementing unique Control-M/Tape facilities.

Customization and Tuning

After Control-M/Tape has been implemented and is operating is a way compatible with the operation of your previous tape management system, you may choose to implement advanced Control-M/Tape features and customization.

-

Combine Control-M/Tape rules by replacing selection criteria (in ON statements) with masks and by implementation of working calendars using the IOA Calendar facility.

-

Customize the tape management environment to maximize benefits provided by Control-M/Tape. This process includes:

-

Tuning of pool, vault, and rule definitions for optimum hardware and system utilization.

-

Reducing the number of rules created during the conversion process by defining generic rules for groups of jobs, data sets, volumes, accounts, and so on.

-

Defining rules according to applications and for types of processing (for example, month-end runs).

-

Defining vault management and pool allocation rules, and modifying existing rules to convert from volume-level retention to data set-level retention.

-

Unique Control-M/Tape Facilities

Control-M/Tape features that perform tasks not previously possible at your site should not be implemented until after the more basic functions. The actual features that are new to your site depend on what tape management system was used previously at your site. Some unique Control-M/Tape features are:

-

Dynamic Data Set Stacking, described in Dynamic Data Set Stacking.

-

Support for external (foreign) tapes, described in 9 Registering External (Foreign) Tapes.

-

DFSMS support, described in DFSMS Support.

-

Fast Positioning, described in the organization and administration chapter of the Control-M/Tape User Guide).

Communities

Communities Support Center

Support Center YouTube

YouTube Twitter

Twitter Facebook

Facebook LinkedIn

LinkedIn