The following overview describes how Control-M/Analyzer integrates into your production environment. The overview consists of the following four topics:

These topics are presented in the form of a graphic illustration (called the Control-M/Analyzer Runtime Environment) in Figure 3.

Production jobs are scheduled and run by operations staff on a daily basis. Jobs process various types of data sources. The data integrity of these data sources can be automatically checked and verified using Control-M/Analyzer.

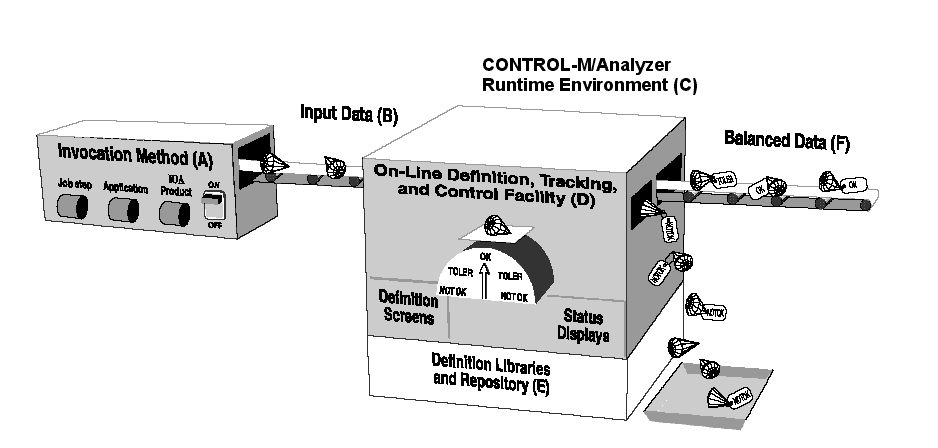

The illustration represents Control-M/Analyzer within your production environment. According to the illustration, the balancing process is initiated by an Invocation Method (A), which is represented by an ON/OFF switch. This switch activates a conveyer belt that loads diamonds into a balancing machine. The various input data sources (B) that can be balanced by Control-M/Analyzer are represented by diamonds.

The Control-M/Analyzer Runtime Environment (C) that performs all balancing operations is diagrammed as a machine. Based on instructions specified by the Online Definition, Tracking, and Control facility (D) and stored in Definition libraries in the Repository (E), each data source is examined. The balancing operation is represented by a scale, which determines if each diamond is OK, TOLER, or NOTOK.

Control-M/Analyzer guarantees that data in your production environment are balanced according to standards you define. The Balanced Data (F) is represented by tagged diamonds. Data that are not within reasonable tolerance limits can be rejected by your production system.

Figure 3 Control-M/Analyzer Overview

Parent Topic |